The Most Durable Protective Coating for Cars

Professional Ceramic Coating Installation in Pottstown, Pennsylvania

What is a Ceramic Coating?

Ceramic coating represents the pinnacle of automotive surface protection technology.

This liquid polymer chemically bonds with your vehicle’s factory paint to create an invisible, permanent shield that transforms how your car looks and performs.

When professionally applied at our Pottstown facility, ceramic coating forms a protective layer that’s measured in microns yet delivers years of unmatched defense against environmental damage.

The science behind ceramic coating involves nanotechnology that fills microscopic imperfections in your paint’s surface.

Once cured, this creates a perfectly smooth, hydrophobic barrier that causes water to bead and roll off effortlessly.

Unlike traditional waxes that sit on top of paint and wash away within weeks, ceramic coating becomes part of your vehicle’s clear coat through a chemical bonding process that can only be removed through intensive machine polishing.

How Ceramic Coating Transforms Your Vehicle

Professional ceramic coating does more than protect your investment. It fundamentally changes how your vehicle interacts with the environment.

Water, dirt, and contaminants that normally stick to paint surfaces simply slide off a ceramic coated vehicle.

This self-cleaning effect means your car stays cleaner between washes and requires significantly less effort to maintain its showroom appearance.

The glossy, mirror-like finish achieved through ceramic coating amplifies your paint’s depth and color intensity.

This enhancement isn’t temporary like detail sprays or waxes. The ceramic layer maintains its brilliant shine year after year, making your vehicle look perpetually new.

Road grime, bug splatter, and bird droppings that would normally etch into unprotected paint can be removed with minimal effort from ceramic coated surfaces.

Ceramic Coating Packages in PA

Why Choose Ceramic Pro Pottstown as Your Coating Installer

Eastern Pennsylvania’s Premier Ceramic Coating Facility

Ceramic Pro Pottstown has established itself as the leading ceramic coating installer serving Collegeville, Royersford, West Chester, Allentown and surrounding Pennsylvania communities.

Our dedication to perfection shows in every vehicle that leaves our facility. We combine cutting-edge coating technology with meticulous preparation processes that ensure optimal results for every application.

Our team undergoes continuous factory training to maintain Elite Dealer certification. This exclusive status means we have access to the most advanced ceramic coating formulas available, including Ceramic Pro ION technology that standard installers cannot obtain.

When you choose our facility, you’re choosing expertise that comes from thousands of successful installations and a commitment to excellence that sets industry standards.

The Ceramic Pro ION Advantage

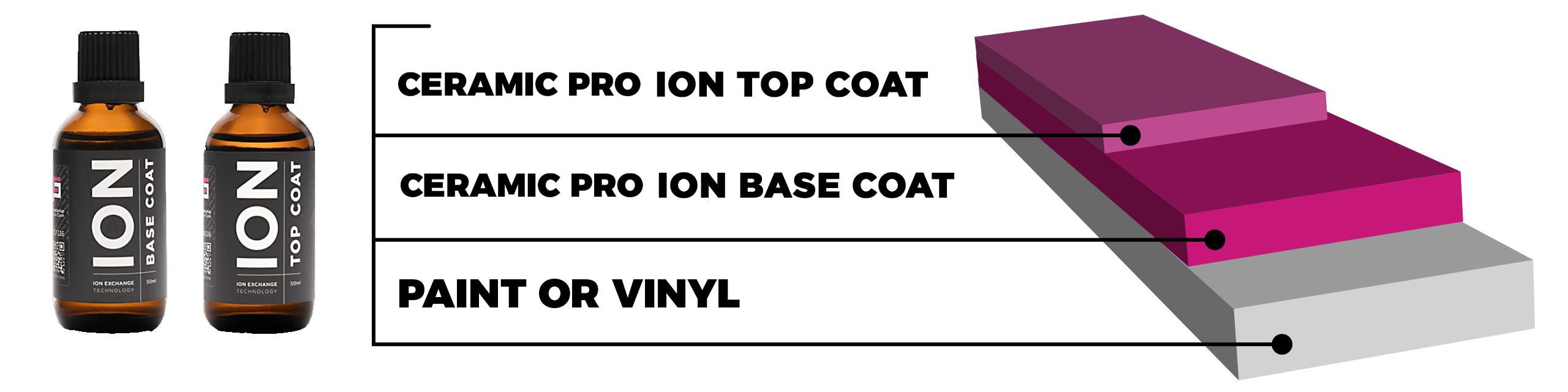

Ceramic Pro ION revolutionizes automotive protection through Ion Exchange Technology.

This breakthrough process forces larger ions into paint’s microscopic imperfections, creating a denser, stronger bond than any previous ceramic coating formula.

The technology mirrors the chemical strengthening used in smartphone screen manufacturing, bringing military-grade durability to automotive applications.

Standard ceramic coatings achieve 9H hardness on the pencil scale. ION exceeds this measurement entirely, providing abrasion resistance previously impossible in paint protection.

One layer of ION base coat equals the protection of multiple layers of traditional ceramic coating, yet maintains perfect flexibility to prevent brittleness or cracking over time.

Why Choose Ceramic Pro Pottstown as Your Coating Installer

Eastern Pennsylvania’s Premier Ceramic Coating Facility

Ceramic Pro Pottstown has established itself as the leading ceramic coating installer serving Collegeville, Royersford, West Chester, Allentown and surrounding Pennsylvania communities.

Our dedication to perfection shows in every vehicle that leaves our facility. We combine cutting-edge coating technology with meticulous preparation processes that ensure optimal results for every application.

Our team undergoes continuous factory training to maintain Elite Dealer certification. This exclusive status means we have access to the most advanced ceramic coating formulas available, including Ceramic Pro ION technology that standard installers cannot obtain.

When you choose our facility, you’re choosing expertise that comes from thousands of successful installations and a commitment to excellence that sets industry standards.

The Ceramic Pro ION Advantage

Ceramic Pro ION revolutionizes automotive protection through Ion Exchange Technology.

This breakthrough process forces larger ions into paint’s microscopic imperfections, creating a denser, stronger bond than any previous ceramic coating formula.

The technology mirrors the chemical strengthening used in smartphone screen manufacturing, bringing military-grade durability to automotive applications.

Standard ceramic coatings achieve 9H hardness on the pencil scale. ION exceeds this measurement entirely, providing abrasion resistance previously impossible in paint protection.

One layer of ION base coat equals the protection of multiple layers of traditional ceramic coating, yet maintains perfect flexibility to prevent brittleness or cracking over time.

Facts About Ceramic Coating Every Car Owner Should Know

Your vehicle faces constant assault from environmental hazards that degrade its appearance and value

New vehicles often arrive with paint damage from dealership lot washing, where automatic car washes and dirty brushes install swirls and scratches before you take delivery.

Traditional waxes and sealants mask these defects temporarily but wash away quickly, leaving paint vulnerable again.

Improper washing techniques cause cumulative damage that compounds over time. Every contaminated wash mitt, every automatic car wash, and every improper drying method adds microscopic scratches that dull your finish.

Professional ceramic coating creates a sacrificial layer that absorbs this damage instead of your paint, preserving the factory finish underneath.

Pennsylvania’s climate presents unique challenges for vehicle preservation. Road salt, acid rain, industrial fallout, and temperature extremes all attack unprotected paint.

Ceramic coating provides a chemical-resistant barrier that prevents these contaminants from reaching your clear coat.

Bird droppings, tree sap, and bug splatter that would normally etch paint within hours can sit on ceramic coated surfaces for days without causing permanent damage.

The Science Behind ION Ceramic Coating Technology

Ion Exchange Technology Explained

Ion Exchange represents a paradigm shift in ceramic coating chemistry. This sophisticated process replaces smaller ions in the coating matrix with larger ions during the curing phase.

The result is a denser molecular structure with reduced free space between particles. This increased density translates directly to superior protection against chemical penetration and physical abrasion.

The same Ion Exchange principle strengthens glass in premium smartphones and tablets. By adapting this technology for automotive applications, Ceramic Pro ION delivers protection that exceeds military specification requirements.

The coating’s molecular structure features pyramid-shaped formations rather than traditional hair-like structures, providing exponentially greater durability against mechanical wear.

Understanding Ceramic Coating Benefits for Your Vehicle

Superior Gloss and Depth Enhancement

Ceramic coating amplifies your paint’s natural beauty by creating an optically clear layer that enhances light reflection. This produces a wet look that surpasses any wax or sealant available.

The coating’s uniform thickness eliminates orange peel texture, creating a glass-smooth surface that photographers call “liquid paint” appearance. This enhanced gloss remains consistent through years of weather exposure and washing.

Permanent Paint Protection That Lasts

Unlike temporary protection products, professional ceramic coating forms a permanent bond with your vehicle’s clear coat. This chemical adhesion means the coating cannot be washed away or degraded by detergents.

The only way to remove properly applied ceramic coating is through machine polishing with abrasive compounds. This permanence translates to years of consistent protection without the need for constant reapplication.

Self-Cleaning Properties Save Time and Money

The hydrophobic surface created by ceramic coating fundamentally changes how contaminants interact with your paint. Water beads into perfect spheres that roll off surfaces, carrying dirt and debris with them.

This self-cleaning effect reduces washing frequency by up to 75 percent while making necessary washes faster and easier. You’ll spend less on car wash supplies and professional detailing services over your vehicle’s lifetime.

Comprehensive Warranty Protection

Our ceramic coating packages include manufacturer-backed warranties that protect your investment.

These warranties cover coating failure, ensuring your protection remains effective throughout the coverage period. We register every installation with CarFax, documenting the added value for potential buyers.

Annual inspection programs maintain warranty validity while ensuring your coating performs optimally year after year.

Why Base Coat and Top Coat Work Together

ION’s two-stage application process maximizes both protection and performance. The base coat provides substantial thickness and creates the primary protective barrier.

This foundation layer bonds permanently with your paint through covalent chemical bonds that become part of the clear coat structure. Its density prevents contamination penetration while its hardness resists scratching and marring.

The ION top coat activates the Ion Exchange reaction while adding hydrophobic properties that create the self-cleaning effect.

Unlike single-layer systems, ION top coat has its own measurable thickness that contributes to overall protection. The molecular structure reduces staining potential while accelerating cure times for faster vehicle delivery.

Why Professional Installation Matters for Ceramic Coating

Professional ceramic coating installation requires controlled environments, specialized equipment, and extensive training that DIY applications cannot replicate.

Our climate-controlled facility maintains optimal temperature and humidity levels essential for proper coating cure. Contamination-free air filtration prevents dust particles from compromising the coating during application.

Surface preparation represents 80 percent of coating success. Our technicians spend hours decontaminating, correcting, and preparing paint surfaces before coating application begins.

Iron fallout removal, clay bar treatment, and machine polishing create the perfect foundation for coating adhesion. Skipping or rushing these steps guarantees premature coating failure.

Application technique determines coating uniformity and longevity. Our certified technicians understand the precise pressure, overlap, and timing required for each coating formula.

Panel-by-panel application ensures complete coverage without high spots or missed areas. Proper flash timing between layers and final inspection under specialized lighting guarantees flawless results.

What You’ll Experience With Ceramic Pro Pottstown

Industry-Leading Warranty Coverage

As a Ceramic Pro Elite Dealer, we offer warranty options unavailable at standard installation centers. Our lifetime warranty program provides permanent protection when combined with annual maintenance visits.

This transferable coverage adds documented value that potential buyers recognize and appreciate. Five-year and seven-year warranties offer flexibility for different ownership timelines while ensuring consistent protection.

Every warranty includes CarFax documentation that becomes part of your vehicle’s permanent history. This third-party verification proves professional ceramic coating installation, distinguishing your vehicle in the used car market.

Warranty coverage includes coating failure, delamination, and performance degradation when maintenance requirements are met.

White Glove Service Experience

We understand that your vehicle represents a significant investment deserving exceptional care.

Our white glove pickup and delivery service eliminates the inconvenience of transportation coordination.

We collect your vehicle from your home or office, perform the ceramic coating installation, and return it detailed and protected.

Clear communication throughout the process ensures you understand exactly what we’re doing and why.

We provide detailed documentation of your vehicle’s condition, the services performed, and care instructions for maintaining your investment.

Our customer service team remains available for questions long after installation, supporting you throughout your ownership experience.

How to care for your Ceramic Coated Vehicle

Ceramic Coating Maintenance Requirements

Initial Curing Period Care

The first 14 days after ceramic coating application are critical for proper cure development.

During this period, avoid using any chemical cleaners or soaps on coated surfaces. If washing becomes necessary, use only clean water and gentle pressure. Park your vehicle in covered areas when possible to prevent water spotting during the cure phase.

Temperature fluctuations can affect curing, so avoid washing your vehicle when surfaces are hot from sun exposure.

Early morning or evening washing prevents thermal shock that could compromise coating integrity.

Follow our detailed care instructions to ensure your coating reaches maximum hardness and hydrophobic performance.

Long-Term Maintenance Protocol

Maintaining your ceramic coating requires specific products and techniques that preserve its protective properties.Use only pH-neutral automotive soaps designed for coated vehicles. Ceramic Pro CARE maintenance spray rejuvenates hydrophobic properties and adds gloss between washes.

Apply this product during drying to enhance water beading and maintain the self-cleaning effect.Avoid automatic car washes with brushes that can introduce swirls into the coating surface. Touchless automatic washes or hand washing with proper techniques preserve coating integrity.

Remove bird droppings and tree sap promptly to prevent etching, though ceramic coating provides significantly more resistance than unprotected paint.

Regular maintenance washing every two weeks prevents contamination buildup that could compromise hydrophobic properties.

Annual professional inspections ensure your coating continues performing optimally while maintaining warranty coverage. Our maintenance programs include coating rejuvenation treatments that restore like-new performance.